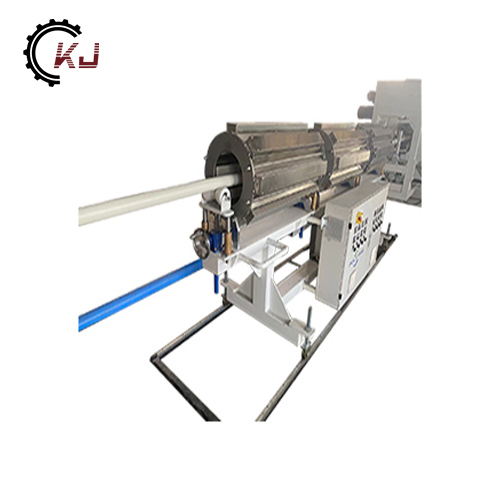

PVC-O Pipe Producing Line

Send Inquiry

The PVC-O Pipe Producing Line from Kangju employs cutting-edge technology to manufacture plastic pipes. Leveraging its unique biaxial stretching process, it significantly reduces material costs for pipe production, achieving savings of over 70%. This advanced approach is gaining increasing popularity in today's market.

Technical data

Model/data Pipe diameter Extruder model Speed Max capacity

FP250 90-250mm LSZ65 1.5-8m/min 300kg/h

FP315 110-315mm LSZ75 0.5-5m/min 500kg/h

FP630 400-630mm LSZ92 0.1-2m/min 800kg/h

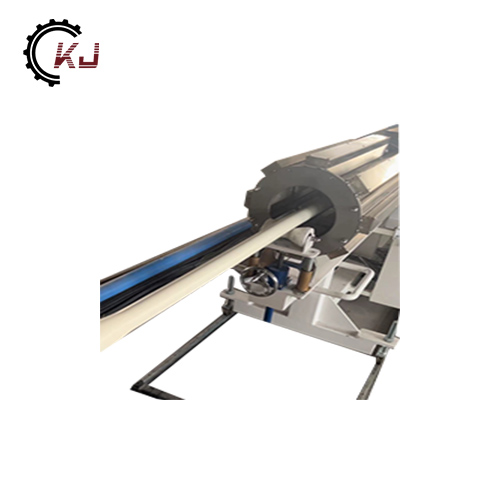

PVC-O pipe represents the next evolution in PVC piping. Through a specialized orientation process known as biaxial stretching technology, which involves both axial and radial stretching, the long-chain PVC molecules within the pipe are aligned bidirectionally. This alignment results in a new PVC pipe that boasts exceptional strength, toughness, impact resistance, and crack resistance.

The stretching orientation process for polymer materials is a transformation that occurs when molecules are arranged from a disordered state to an ordered one. This rearrangement takes place under the application of external force, typically at a temperature range between the glass transition temperature and the melting temperature (often near the softening point). In biaxial stretching, the material is stretched in two perpendicular directions, combining the strength gained from both axial and radial stretching. This enhances the material's strength not only along the stretched surface but also perpendicular to it, leading to an overall improvement in structural integrity.

When compared to traditional PVC pipes, PVC-O pipes feature a significantly thinner wall thickness yet exhibit remarkable high-pressure tolerance. By utilizing a PVC-O pipe making machine, clients can achieve significant savings in material costs.

PVC-O pipes are manufactured through a bidirectional stretching process, utilizing a raw material composition that is largely similar to standard PVC-U pipes. However, the performance of PVC-O pipes is drastically superior to PVC-U pipes. The impact resistance of PVC-O pipes is enhanced approximately four times, while maintaining toughness even at temperatures of -20°C. Additionally, under the same pressure conditions, the wall thickness of PVC-O pipes is reduced by half compared to PVC-U pipes, resulting in a remarkable 47% savings in raw material usage. This thinner wall thickness also translates to increased water conveyance capacity, lighter pipes for easier installation, and lower transportation costs.