Home

>

Products > Plastic Recycling Machine

> PP PE Plastic Film HDPE Bottles Waste Recycling Machine

>

plastic bottle recycling machine

plastic bottle recycling machine

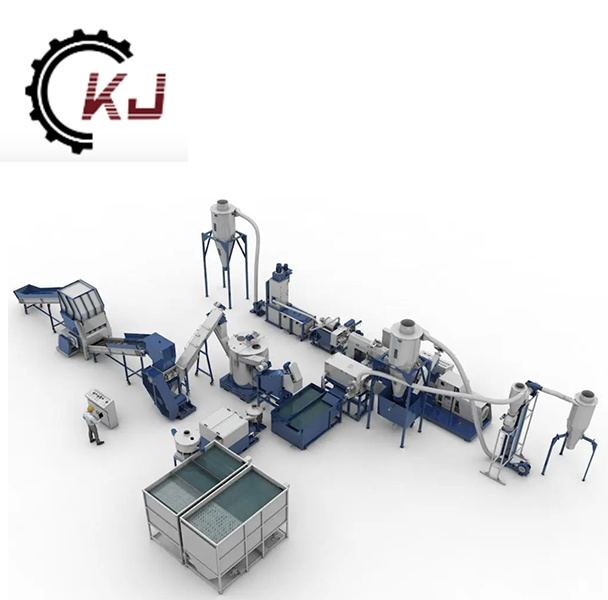

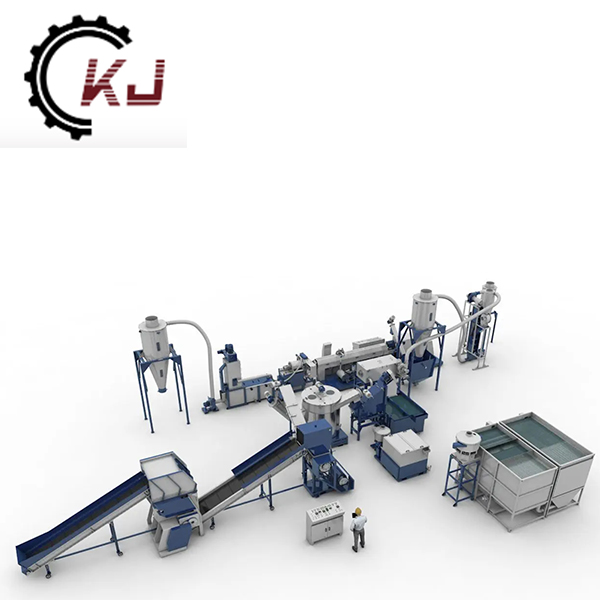

Waste plastic pet bottle recycling factory machine line plastic bottle recycling machine price can be designed according to the dirtiness of the PP PE film/bag and ensure the quality of the final product.

Coordinate the production line with subsequent programming work (granulation system), which will turn waste and dirty PP PE films/bags into PP PE granular materials and produce new PP PE products.

Send Inquiry

Product Description

Waste plastic pet bottle recycling factory machine line plastic bottle recycling machine price

Describe:

Material: Plastic PP PE film/PP PE woven bag/HDPE LDPE PP pet bottle/nylon bag

Product size: 30-100mm or customized

Moisture content: <3%

main feature:

1) The whole production line is used for crushing, washing, dehydrating and drying PP, PE film.

2) It has the advantages of simple structure, convenient operation, large capacity, low energy consumption, safety and reliability.

3) The entire production line is automatically controlled, with compact structure, high production efficiency and good cleanliness.

4) Production capacity: 100-3000kg/h.

Machine specifications:Capacity (kg/hour)3005001000Crusher motor (kW)304555Total power (kW)120150250Moisture contentless than 3%less than 3%less than 3%Total length (meters)202638Process flow:

♦ Belt Conveyor : Convey dirty plastic films or bags into the crusher. If you have a lot of scrap metal, you may need a metal detector.

♦ Crusher : It can be crushed with water to cut the plastic film or bag into small pieces.

♦ Screw loader : Load the film sheets into the next step

♦ High-speed friction washing machine : washes away sand, mud and loads materials

♦ Cleaning tank : Separates sand, soil and other dirt

♦ S queezing dryer/horizontal dehydrator/press drying granulator : remove water from materials

Main machine list

| name | (kilowatt)Motor Power | (mm)size | (T/H)Water Consumption | (mm)stainless steel standard | electrical standards |

| Belt conveyor | 1.5kW | 4000*600*2100mm | - | - | According to customer's standards |

| Crusher | 37kW | 1800*1500*3000mm | 0.6-1.0 | - | |

| spiral charger | 1.5kW | 3300*420*1600mm | - | 3-5 | |

| Belt conveyor | 1.5kW | 4000*600*2100mm | - | - | |

| Crusher | 37kW | 1800*1500*3000mm | 0.6-1.0 | - | |

| spiral charger | 1.5kW | 3300*420*1600mm | - | 3-5 | |

| floating sink | 2.2*2KW | 6000*1250*1700mm | 4-5 | 3-5 | |

| spiral charger | 1.5kW | 3000*420*1450mm | - | 3-5 | |

| High speed friction washing machine | 22kW | 3200*1200*1800mm | 1-2 | 3-5 | |

| spiral charger | 1.5kW | 3000*420*1460mm | - | 3-5 | |

| Dehydrator | 45kW | 1750*1420*1770mm | - | 5 | |

| Drying system-1 | 28kW | 3700*1000*2000mm | - | 3-5 | |

| Transitional storage | - | 1200*1000*3000mm | - | - | |

| Drying system-2 | 28kW | 3700*1000*2000mm | - | 3-5 | |

| Storage hopper | 2.2kW | 3700*1500*3500mm | - | - | |

| Electrical cabinet | - | 2000*450*1780mm | - | - |

Hot Tags: plastic bottle recycling machine, Manufacturer, Supplier, China, Factory, Low Price, Buy, Quality

Product Tag

Related Categories

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy