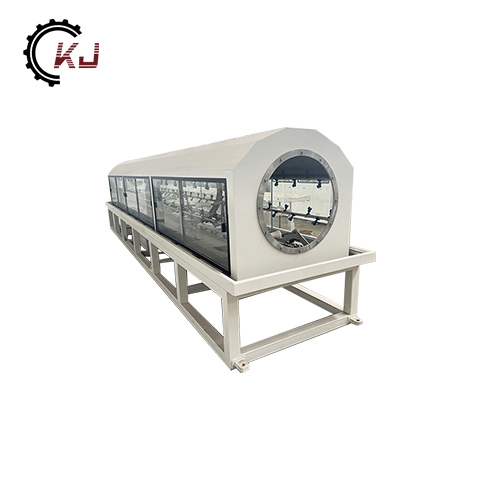

450-630 MM PE Plastic Irrigation Pipe Making Machine

Send Inquiry

PE Pipe

■ Good hygienic performance: no heavy metal salt stabilizer is added during PE pipe processing, the material is non-toxic, no scaling layer, and no bacteria breeding, which solves the hidden danger of secondary pollution of urban drinking water.

■ Excellent corrosion resistance: Except for a few strong oxidants, it can withstand the erosion of a variety of chemical media; no electrochemical corrosion.

■ Long service life: PE pipe can be used safely for more than 50 years under rated temperature andpressure.

■ Better impact resistance: PE pipe has good toughness and high impact resistance, and heavy objects directly pass through the pipe, which will not cause the pipe to be broken.

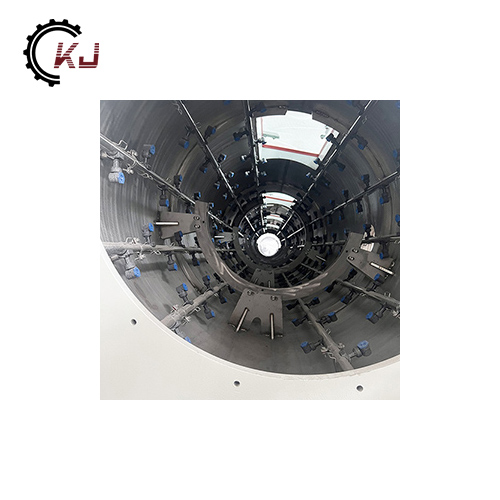

This 450-630 Mm PE Plastic Irrigation Pipe Making Machine is mainly used for producing large diameter HDPE/MDPE pipe. The pipe has some excellent features such as heating resistant, aging resistant, high mechanical strength, environmental stress cracks resistant, good creep resistant,etc. It is a preferred gas conduit for ductwork systems between city and its suburb, water supply in city. The unit comprises extruder,co-extruder, pipe die-head,vacuum cooling water tanks, haul-off machine,cutting machine, stacker etc. Extruder and haul-off machine synchronous frequency conversion control. Haul-off machine have 2-claw/3-claw/4-claw/6-claw/8-claw/12-claw type ect. Production line with reliable performance and high efficiency. HDPE pipe can be single-layer or composited multi-layer, according to customer requirements to add online measurement control system.