China hdpe extruder Manufacturer, Supplier, Factory

We've been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for hdpe extruder,plastic tube making machine,hdpe pipe machine,hdpe machine,plastic pipe extrusion line, Adhering on the company principle of mutual gains, we have won superior popularity amid our shoppers because of our excellent products and services, excellent products and aggressive selling prices. We warmly welcome shoppers from home and overseas to cooperate with us for common achievements.

hdpe extruder, Our company insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thank all old and new customers' support. We'll keep working hard and offering you the highest-quality goods and service.

Hot Products

Plastic Film Woven Bags Waste Recycling Machine

The Plastic Film Woven Bags Waste Recycling Machine is extensively employed for recycling and cleansing discarded PE/PP films, shopping bags, woven bags, HDPE milk bottles, rigid PE/PP containers, buckets, and other similar items. This plastic waste recycling and washing plant is capable of crushing, washing, dewatering, and drying waste PP and PE materials. It encompasses the entire production process, from crushing and washing to drying the raw materials. The machine boasts features such as high efficiency, stability, and a large processing capacity. Whatever your requirements may be, we can accommodate them.PVC Pulverizer Machine

The brand-new MF series plastic pulverizer belongs to the Disc-type pulverizer series, whichdisc diameter from 350mm to 800mm.This PVC Pulverizer Machine is high speed, precision grinders for theprocessing of medium hard, impact resistant and friable materials, for example PE、PVC、PP、ABS、PA、EVA、PET、PS、PPS、EPS、PC、Foam、Cow leather and so on.PE PP PVC double-wall corrugated pipe extrusion machine

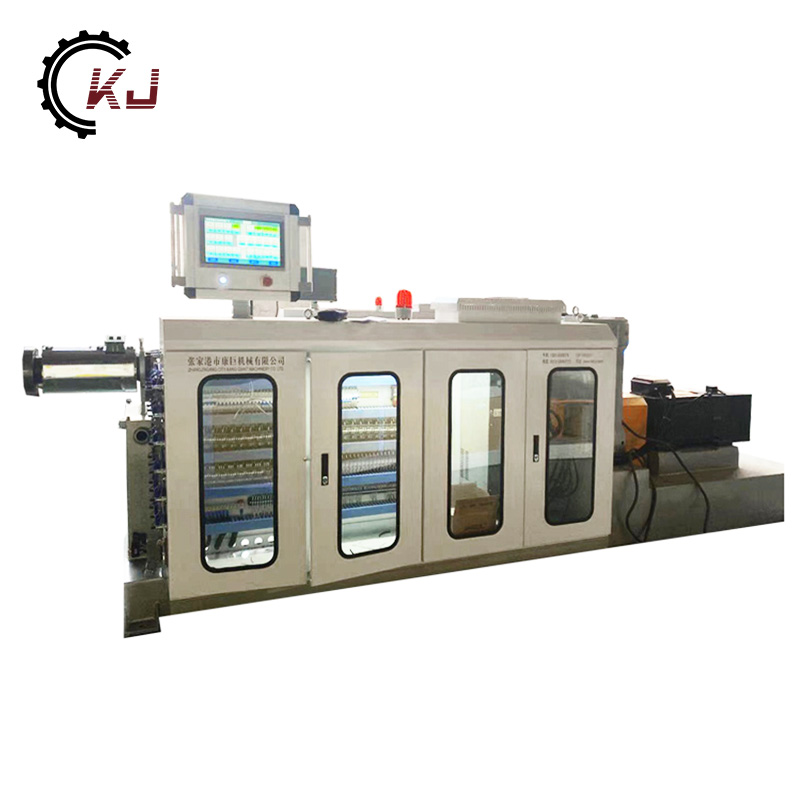

You are welcomed to come to our factory to buy the latest selling, low price, and high-quality PE PP PVC double-wall corrugated pipe extrusion machine. We look forward to cooperating with you.PVC PP PE Pulverizing Machine

Kangju offers the SMF series of PVC PP PE Pulverizing Machines, ranging in diameter from 300 to 800 mm. These pulverizers are designed for high-speed, precise grinding of medium-hard, impact-resistant, and brittle materials. The material to be pulverized is fed through the center of a vertically mounted, stationary grinding disc that rotates concentrically with an identically sized, high-speed rotating disc. As centrifugal force propels the material through the grinding zone, the resulting powder is efficiently collected by a blower and cyclone system. Depending on specific needs, these machines can be equipped with either one-piece grinding discs or segmented grinding discs.Plastic Profile Extrusion Machine

China kangju® high quality WPC Plastic profile extrusion machine line includes material feeder, twin screw extruder, water cooling& calibration table, hauling off machine, cutting machine and stacker.Easy Operation Industrial Crusher Machine

High quality easy operation industrial crusher machine is a machine designed to crush or reduce the size of various materials, such as rocks, ores, minerals, or industrial waste. It is typically used in industries like mining, construction, recycling, and manufacturing, where large quantities of materials need to be processed efficiently. The focus of an easy operation industrial crusher machine is to provide a user-friendly interface and simplified operation for operators.