Twin-Screw Extruder for HDPE Pipe

Send Inquiry

Double wall corrugated pipe , polyethylene corrugated pipe, corrugated pipe, double wall pipe, are all the names of the pipe consisting of two layers of polyethylene.

The inner layer is meticulously polished, while the outer layer sports a corrugated and rippling design. This specific shape and geometry confer remarkable resistance and tolerance to all types of surface and subsurface pressures, accommodating both live and dead loads beneath the ground. Double-wall corrugated pipes are categorized into three distinct pressure classes—16, 31.5, and 64 kilonewton—each suitable for specific applications based on soil surface type and surface/subsurface load pressures.

|

Item |

Name |

Qty |

|

1.1 |

Extruder |

one set |

|

1.2 |

Mould |

one set |

|

1.3 |

Corrugate shaping machine |

one set |

|

1.4 |

Winder |

one set |

|

1.5 |

Electrical appliance |

one set |

Why double wall corrugated pipe?

Double-wall corrugated polyethylene pipes exhibit high resistance thanks to their soil volume and ring stiffness. These pipes typically withstand an inner pressure of 2 to 4 bars, rendering them unsuitable for high-pressure networks. To connect these corrugated pipes, one can use couplers, washers, or extruder welding. The estimated lifespan of corrugated pipes ranges from 50 to 100 years, depending on the raw materials used, production conditions, storage, and maintenance.

When burying the pipe to withstand environmental conditions, several factors must be considered. One crucial aspect for corrugated pipes is the pH of the soil. Polyethylene corrugated pipes have been in use for nearly a decade, prized for their resilience against subsidence and deterioration, ease of installation, and resistance to soil movement and pressure.

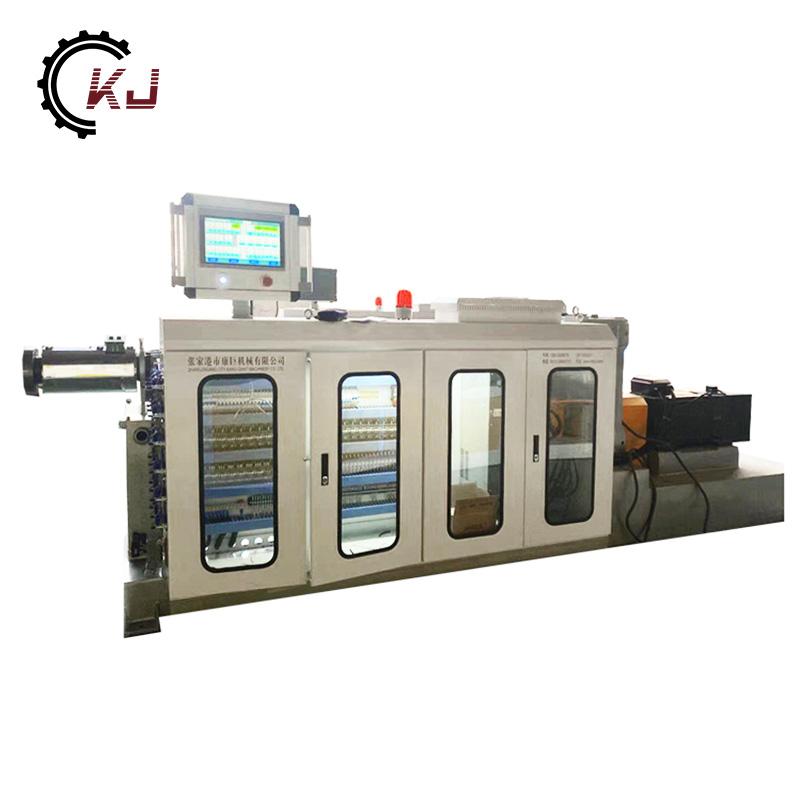

Twin-Screw Extruder for HDPE Pipe This production line is capable of continuously manufacturing corrugated pipes from various materials, including PE, PP, PVC, EVA, and even PA corrugated pipes (by adjusting the screw's L:D ratio). The SJDBGZ series Twin-Screw Extruder for HDPE Pipe, developed by our company, utilizes gears to operate modules and templates. This ensures efficient water circulating cooling and air cooling of the products, guaranteeing high-speed molding, uniform corrugation, and smooth inner and outer pipe walls.

Machine list (Twin-Screw Extruder for HDPE Pipe)

Application:

1. Plastic single-wall corrugated pipes exhibit several notable features, including high temperature resistance, corrosion and abrasion resistance, high strength, and good flexibility.

2. These pipes find widespread application in various fields such as automotive wiring, electric threading pipes, machine tool circuitry, protective piping for lighting wires, as well as tubing for air conditioners, vacuum cleaners, and washing machines.

3. These corrugated pipes are particularly favored for use as wires in high-end automobiles.