China Double Walled Corrugated HDPE Pipe Extruder Making Machine Manufacturer, Supplier, Factory

We thinks what shoppers think, the urgency of urgency to act during the interests of a buyer position of basic principle, allowing for greater top quality, lessen processing costs, costs are extra reasonable, won the new and previous buyers the support and affirmation for Double Walled Corrugated HDPE Pipe Extruder Making Machine,High-speed HDPE Corrugated Pipe Extruder,Extrusion Line for HDPE Corrugated Pipe,Large Diameter HDPE Corrugated Pipe Extruder,HDPE Corrugated Pipe Extruder Machine, Excellent excellent, competitive selling prices, prompt delivery and dependable provider are guaranteed Kindly let us know your quantity requirement under each size category so that we will inform you accordingly.

Double Walled Corrugated HDPE Pipe Extruder Making Machine, Our company has already had a lot of top factories and expert technology teams in China, offering the best solutions, techniques and services to worldwide customers. Honesty is our principle, professional operation is our work, service is our goal, and customers' satisfaction is our future!

Hot Products

wood plastic composite profile extrusion production line

wood plastic composite profile extrusion production line Plastic composite wood plastic profile planking extrusion production line manufacturing machine polyethylene polypropylene wood plastic wood ABB PVC profile extruderPlastic Tube Making Machine

Kangju Machinery's Plastic Tube Making Machine features an automatic operation system and PLC control system, which helps to minimize labor costs while boosting efficiency. The comprehensive machine comprises a twin-screw extruder, vacuum box, cooling box, tractor, and stacker.Plastic Shredder

The Kangju Machinery's high-quality Plastic Shredder is specifically designed to efficiently crush a diverse range of materials, including plastics, rubbers, fibers, paper, wood, bulky hollow items (like plastic drums), and mixed waste that may even contain metals or pre-shredded items like sand scrap. To enhance productivity, the shredder can be equipped with a compression device for crushing hollow materials. Additionally, a rotating screen can be incorporated to regulate the discharge particle size. Operating at a low speed, this double-shaft shredder effectively minimizes noise and dust emissions, meeting stringent environmental standards.SPC LVT Flooring Extrusion Line

SPC LVT flooring extrusion line is a great cost-effective choice for main floors of residential homes with normal wear in kitchens, living spaces or bathrooms. It is also excellent for basements where you’ll benefit from waterproofing, secondary vacation homes or rental homes as it is very low maintenance, can take a beating and is cost-effective to change out to maintain a modern look.HDPE Corrugated Pipe Extrusion Line

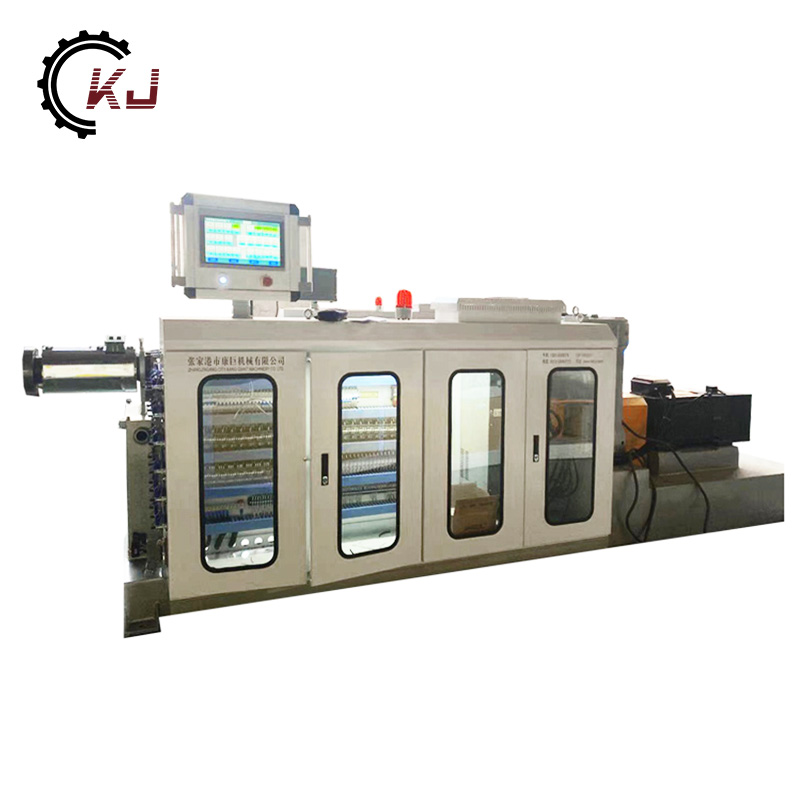

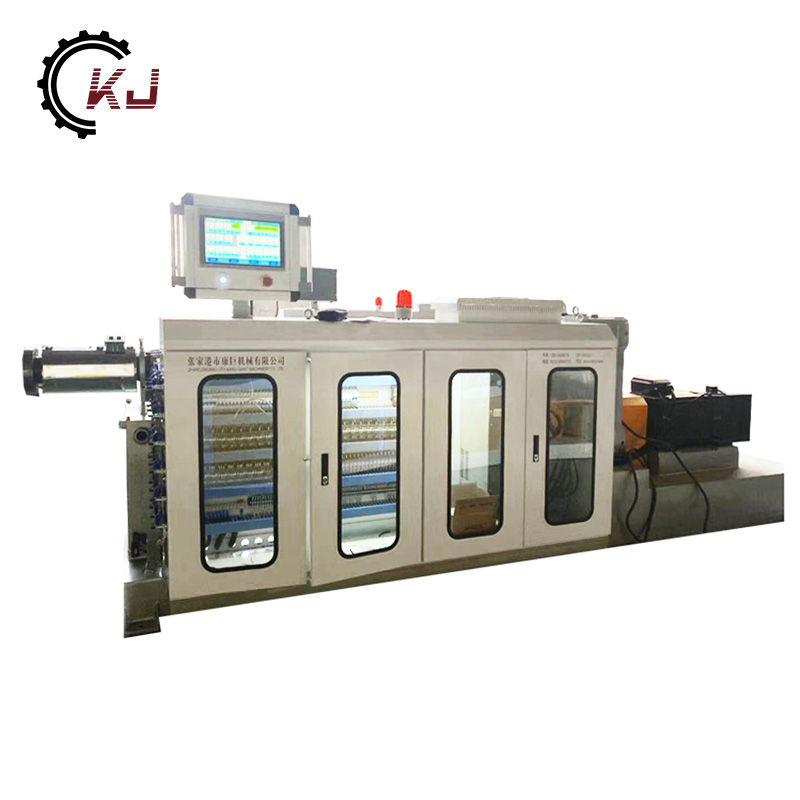

The HDPE Corrugated Pipe Extrusion Line utilizes an extrusion and forming process, offering reliable quality and high efficiency. Double wall corrugated pipe, with its superior wall structure design, stands out among other plastic pipe options. Its lightweight construction not only reduces production costs but also enhances market competitiveness. This type of pipe finds widespread application across various fields, serving as a substitute for concrete and iron pipes. Its popularity stems from its ease of connection, simple installation of accessories, and dependable quality.Wood Plastic Composite WPC Machine

The Wood Plastic Composite WPC Machine is a crucial component of the WPC machine. It combines and melts the wood and plastic materials, forming a uniform mixture. This mixture is then forced through a die to shape it into the desired profile or board. The die is a critical component that shapes the WPC material into the desired profile or board. After exiting the die, the product moves onto a calibration table, which helps in maintaining its shape and dimensions.