China plastic granules dryer Manufacturer, Supplier, Factory

Good quality comes initial; company is foremost; small business is cooperation" is our business philosophy which is frequently observed and pursued by our business for plastic granules dryer,plastic hopper dryer,plastic dryer machine,plastic dryer,hopper dryer plastic granules, We give priority to good quality and customer fulfillment and for this we follow stringent excellent control measures. We've in-house testing facilities where our goods are tested on each and every aspect at different processing stages. Owning to latest technologies, we facilitate our prospects with custom-made production facility.

plastic granules dryer, Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing solutions, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

Hot Products

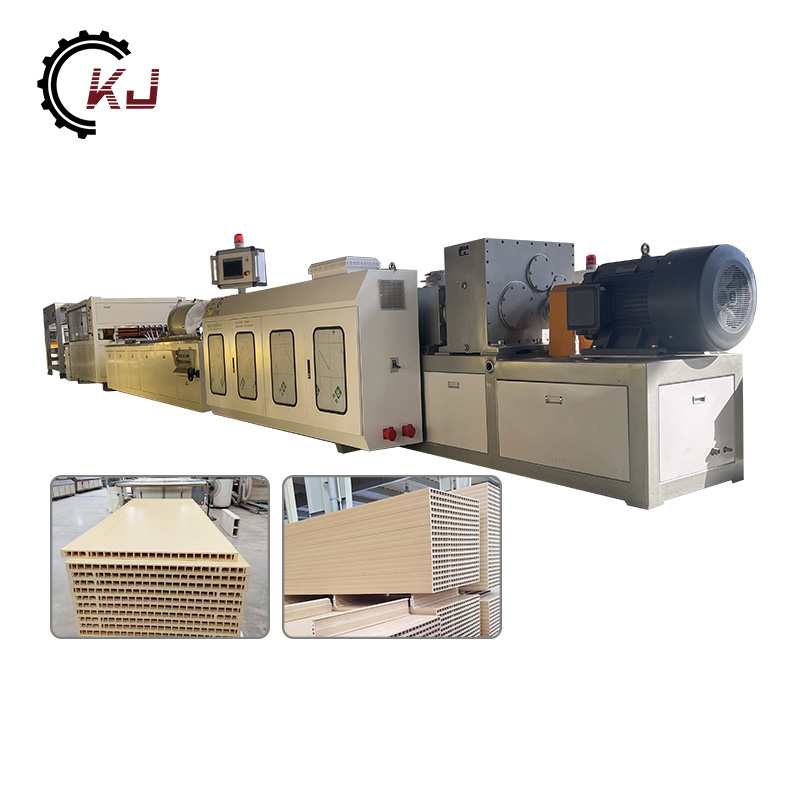

PVC Window and Door Profile Extruder Machine Extrusion Line

PVC window and door profile extruder machine extrusion line making machine PVC Window Profile Machine This line is used to produce PVC window profile by twin screw extruder. This line are consisted of twin screw extruder, extrusionmould, calibration platform; haul-off machine, cutting machine, stacker, etc.MBBR biological filter media suspended filler making machine

MBBR Carrier media is is a microbial carrier used in the MBBR process, mainly to provide a suitable growth environment for microorganisms.You can rest assured to buy MBBR biological filter media suspended filler making machine from our factory.Plastic Door Frame Production Machine Line

The Plastic Door Frame Production Machine Line provided by Kangju supplier specializes in the extrusion of WPC door and window profiles. This production line includes vital components such as a conical twin-screw extruder, vacuum forming table, spray cooling tank, profile haul-off machine, profile cutting machine, and profile stacker. These components work together seamlessly to ensure the efficient and precise manufacturing of WPC door and window profiles, meeting the quality standards expected in the industry.PE Pulverizer Machine

The PE Pulverizer Machine machine of the SMF series are available with diameter from 300 to 800 mm. These plastic pulverizer machines are high speed, precision grinders for the processing of medium hard, impact resistant and friable materials. The material to be pulverized is introduced through the centre of a vertically fixed grinding disc which is mounted concentrically with an identical high speed rotating disc. Centrifugal force carries the material through the grinding area and the resulting powder is collected with a blower and cyclone system. Depending on the application the machines can be equipped with one piece grinding discs or grinding segments.Plastic Shredder

The Kangju Machinery's high-quality Plastic Shredder is specifically designed to efficiently crush a diverse range of materials, including plastics, rubbers, fibers, paper, wood, bulky hollow items (like plastic drums), and mixed waste that may even contain metals or pre-shredded items like sand scrap. To enhance productivity, the shredder can be equipped with a compression device for crushing hollow materials. Additionally, a rotating screen can be incorporated to regulate the discharge particle size. Operating at a low speed, this double-shaft shredder effectively minimizes noise and dust emissions, meeting stringent environmental standards.PVC Edge Band Production Line

PVC edge band production line extrusion machine with double screw extruder is used to produce PVC edge banding tape. For different size edge banding will need change mould. This type machine can be 2 cavity, 4 cavity, 6 cavity or 8 cavity. The size of edge banding, width 19mm-54mm and thickness 0.4mm-2mm.