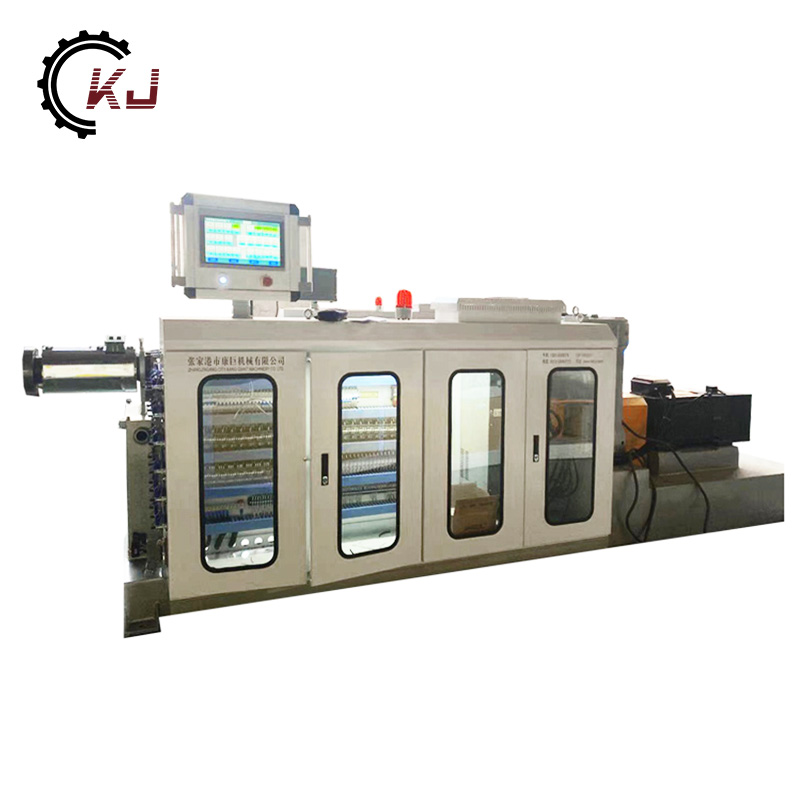

China PPR Hot Cold Water Pipe Production Line Manufacturer, Supplier, Factory

The key to our success is "Good Solution Top quality, Reasonable Value and Efficient Service" for PPR Hot Cold Water Pipe Production Line,PPR Pipe Production Line,PPR Pipe Hot And Cold Water Pipe Extruder,PPR Hot Water Cold Pipe Machine,Ppr For Cold Water Pipe Production Line, Seeing believes! We sincerely welcome the new clients overseas to setup business enterprise interactions and also be expecting to consolidate the relationships while using the long-established prospects.

PPR Hot Cold Water Pipe Production Line, We set a strict quality control system. We now have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. You should feel free to contact us for further information and we will present you competitive price list then.

Hot Products

PE Sleeve Pipe Calibrator

The function of the sizing sleeve is mainly to cool down the tube blank of the PE Sleeve Pipe Calibrator, and fix the outer diameter of the tube blank and trim the surface of the tube.Twin-Screw Extruder for HDPE Pipe

The Kangju Supplier offers a 315mm Twin-Screw Extruder for HDPE Pipe production. This extruder utilizes an extrusion and forming process, providing dependable quality and impressive efficiency. When compared to other plastic pipe wall designs, the double-wall corrugated pipe stands out with its exceptional wall structure. Its lightweight design contributes to reduced production costs, thereby enhancing market competitiveness. This pipe, with its easy connectivity, accessory installation, and reliable quality, has found widespread use in various applications, often replacing traditional concrete and iron pipes.800mm cosmetic PE tube/pipe extrusion production line

The following is the introduction of high quality 800mm cosmetic PE tube/pipe extrusion production line, hoping to help you better understand it. Welcome new and old customers to continue to cooperate with us to create a better future!Automatic PET Sheet Production Line

The screw is tailored with a parallel twin-screw configuration, specifically for PET applications. It features venting capabilities, uniform plasticization, an oblique three-roll calender design, and an L-shaped calender design. To ensure the product's superior toughness, the roller temperature can be precisely adjusted via a mold temperature controller. The Automatic PET Sheet Production Line from Zhejiang Kangju Machinery boasts high transparency and comes equipped with a pre-coated silicone oil device, guaranteeing smooth sheet release during secondary processing. Additionally, thickness measurements are accurately taken with a dial gauge, and the winding process is automatically tensioned for consistent results.HDPE Corrugated Pipe Extruder

315mm hdpe corrugated pipe extruder machine/Double wall corrugated DWC pipe machine PE/HDPE/PVC double wall corrugated pipe extrusion line adopts extruding and forming process, it has the featuresof reliable quality and high efficiency.Compared with other plastic pipe wall structure ,double wall corrugated pipe has excellent wall structure design,its low weight reach the lower production cost and improve the market competitiveness.The pipe is widely used in various field instead of concrete pipe and iron pipes,because it has excellent features such as:easy connected and accessiories installed,and quality reliable.Wpc Wall Panel Machine

The following is the introduction of high quality Wpc Wall Panel Machine, hoping to help you better understand WPC PVC Wall Panel Machine Production Line. Welcome new and old customers to continue to cooperate with us to create a better future!