China PPR Pipe Production Line Manufacturer, Supplier, Factory

We often persist with the theory "Quality To start with, Prestige Supreme". We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for PPR Pipe Production Line,PPR Hot Cold Water Pipe Production Line,PPR Pipe Hot And Cold Water Pipe Extruder,PPR Hot Water Cold Pipe Machine,Ppr For Cold Water Pipe Production Line, Our corporation is dedicated to giving customers with superior and secure excellent items at competitive rate, creating just about every customer content with our services and products.

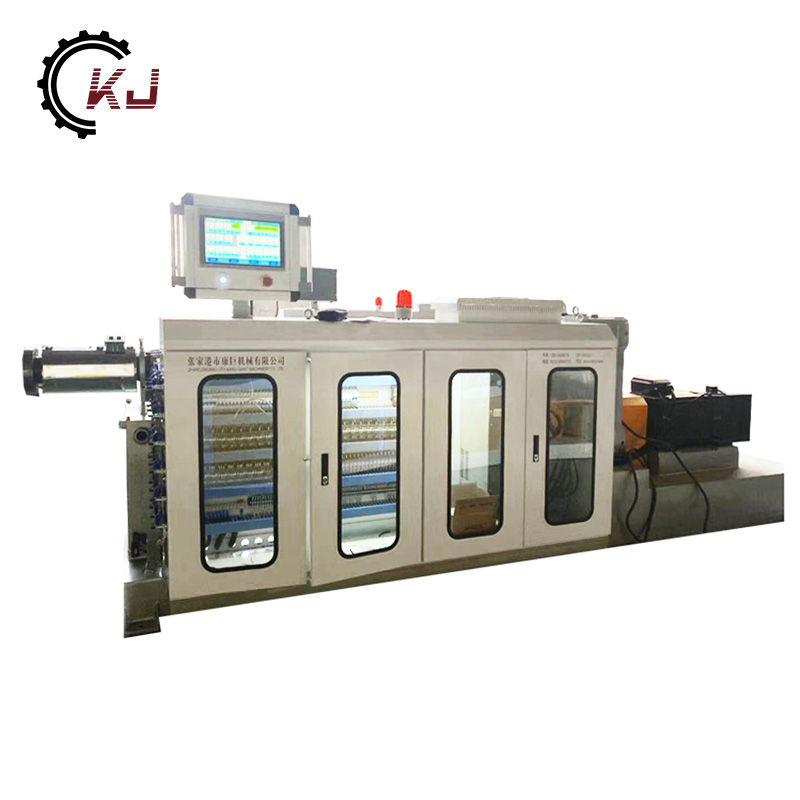

PPR Pipe Production Line, Immediate and expert after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent for you for any comprehensive acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Hot Products

PP PE Plastic Film Waste Recycling Machine

The PP PE Plastic Film Waste Recycling Machine washing plant is widely used to Recycle and Wash the waste PE/PP Film,Shopping bags, Woven bags, HDPE milk bottles, Rigid PE/PP containers, buckets and so on. plastic garbage recycling machine washing plant can crush, wash, dewater and dry waste PP, PE material. This is a whole production line from crushing,washing to drying the raw material.It has features as high efficiency, working stable, large capacity etc. Whatever request you have we can meet.Plastic Washing Recycling Line

Kangju's Industrial Plastic Washing Recycling Line efficiently tackles a broad spectrum of plastic waste, spanning both hard and soft materials such as agricultural films, greenhouse covers, packaging films, PE scrap film, PP scrap film, PVC scrap film, industrial-grade films, printed films, and more.WPC Wall Panel Production Line

WPC wall panel production lines are used in the construction industry to manufacture wall cladding and siding that offer the aesthetics of wood with the durability and low maintenance of plastic. These panels are often used for both interior and exterior wall applications.Recycle Plastic ASA PVC Roofing Tile Production Line

The Kangju Recycle Plastic ASA PVC Roofing Tile Production Line is mainly used in the production of plastic glazed tile.The plastic glazed tiles are widely used in the garden-style factory,tourist scenic spots, pavilions,hotels,family building, etc.PVC PP PE Pulverizing Machine

Kangju offers the SMF series of PVC PP PE Pulverizing Machines, ranging in diameter from 300 to 800 mm. These pulverizers are designed for high-speed, precise grinding of medium-hard, impact-resistant, and brittle materials. The material to be pulverized is fed through the center of a vertically mounted, stationary grinding disc that rotates concentrically with an identically sized, high-speed rotating disc. As centrifugal force propels the material through the grinding zone, the resulting powder is efficiently collected by a blower and cyclone system. Depending on specific needs, these machines can be equipped with either one-piece grinding discs or segmented grinding discs.PVC edge banding production line pvc edge band making machine banding extrusion line

As the professional manufacturer, we would like to provide you high quality PVC edge banding production line pvc edge band making machine banding extrusion line.