China window frame profile making machine Manufacturer, Supplier, Factory

Our advancement depends over the superior machines, exceptional talents and continually strengthened technology forces for window frame profile making machine,PP PE WPC outdoor decking making machine,wood plastic composite profile extrusion production line,PVC WPC PE wall panel production line, We welcome new and aged shoppers from all walks of daily life to call us for long term business associations and mutual accomplishment!

window frame profile making machine, We give good quality but unbeatable low price and the best service. Welcome to post your samples and color ring to us .We are going to produce the items according to your request. If you are interested in any solutions we provide, remember to feel free to contact us directly by mail, fax, telephone or internet. We have been here to answer your questions from Monday to Saturday and looking forward to cooperating with you.

Hot Products

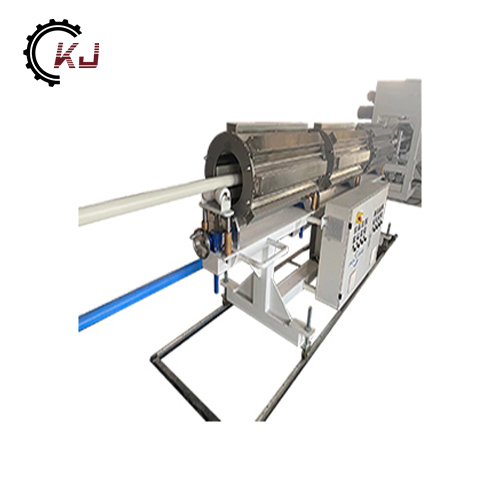

HDPE Pipe Making Machine

High quality HDPE Pipe Making Machine is offered by China manufacturer Kangju. This machine utilizes precise processes and advanced technology to transform HDPE materials into pipes of various specifications and lengths. These pipes are widely used in construction, municipal, industrial, agricultural, and other fields. The HDPE Pipe Making Machine typically comprises crucial components such as a material feeding system, extrusion molding system, cooling system, cutting system, and a control system, ensuring the production of high-quality and standard-compliant HDPE pipes.Plastic Tube Making Machine

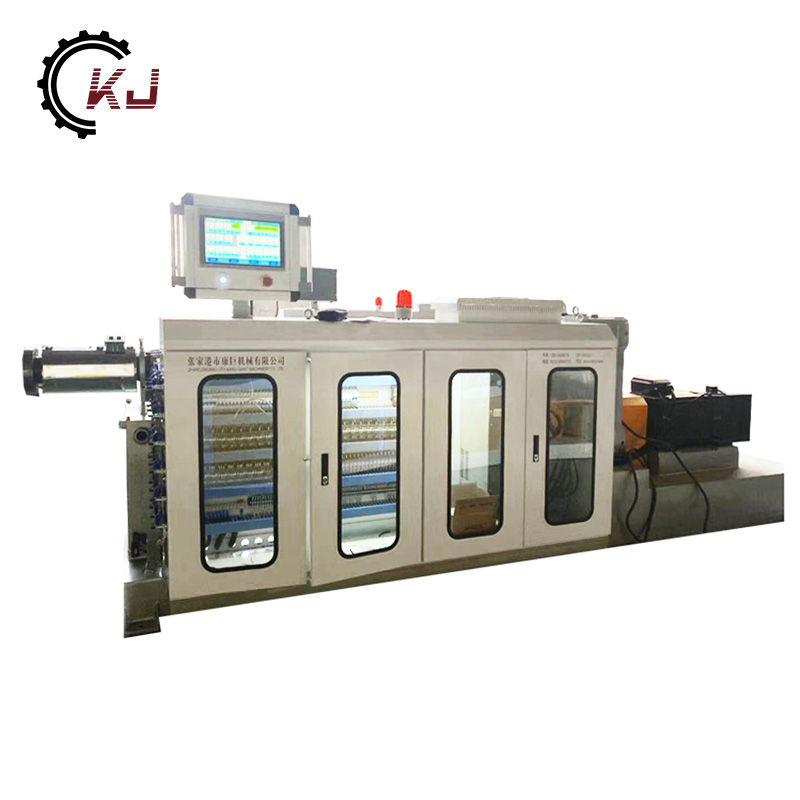

Kangju Machinery's Plastic Tube Making Machine features an automatic operation system and PLC control system, which helps to minimize labor costs while boosting efficiency. The comprehensive machine comprises a twin-screw extruder, vacuum box, cooling box, tractor, and stacker.wood plastic composite profile extrusion production line

wood plastic composite profile extrusion production line Plastic composite wood plastic profile planking extrusion production line manufacturing machine polyethylene polypropylene wood plastic wood ABB PVC profile extruderEasy Operation Industrial Crusher Machine

High quality easy operation industrial crusher machine is a machine designed to crush or reduce the size of various materials, such as rocks, ores, minerals, or industrial waste. It is typically used in industries like mining, construction, recycling, and manufacturing, where large quantities of materials need to be processed efficiently. The focus of an easy operation industrial crusher machine is to provide a user-friendly interface and simplified operation for operators.Pvc Edge Banding Extrusion Line

Pvc Edge Banding Extrusion Line with double screw extruder is used to produce PVC edge banding tape. For different size edge banding will need change mould. This type machine can be 2 cavity, 4 cavity, 6 cavity or 8 cavity. The size of edge banding, width 19mm-54mm and thickness 0.4mm-2mm.PVC Edge Band Making Machine

If you're looking for a reliable and efficient machine that can produce high-quality PVC edge bands, then look no further than Kangju's PVC Edge Band Making Machine. It's perfect for medium to large-scale production and can take your manufacturing process to the next level.