China Wood plastic composite products manufacturing machine Manufacturer, Supplier, Factory

We purpose to understand high quality disfigurement with the output and supply the top service to domestic and overseas buyers wholeheartedly for Wood plastic composite products manufacturing machine,pvc Pe Pp Wpc door floor decorative profile sheet extrusion production line,WPC floor making machine,WPC floors, fences, gazebos, benches, trash cans making machine line, Seeing believes! We sincerely welcome the new prospects abroad to set up company interactions and also expect to consolidate the interactions with all the long-established clients.

Wood plastic composite products manufacturing machine, Our staffs are rich in experience and trained strictly, with professional knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to provide the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we will develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

Hot Products

PVC Powder Micronizing Equipment

Kangju Machinery, as a professional manufacturer and reliable supplier, aims to offer you superior PVC Powder Micronizing Equipment that meets your exact requirements.Plastic Pipe Extrusion Mould for Extruder Machine

Plastic Extrusion mold is a kind of molding mold, but his way of discharging is to achieve through the action of extrusion.Plastic Pipe Extrusion Mould for Extruder Machine is widely used in aluminum shaped structure and also in plastic parts.In the front end of the extruder, used for making pipe, or profile. In short, the mold is used to shape the tool, this tool is composed of various parts, different mold is composed of different parts, it mainly through the formation of material physical state change to achieve the shape of the object processing.Twin-Screw Extruder for HDPE Pipe

The Kangju Supplier offers a 315mm Twin-Screw Extruder for HDPE Pipe production. This extruder utilizes an extrusion and forming process, providing dependable quality and impressive efficiency. When compared to other plastic pipe wall designs, the double-wall corrugated pipe stands out with its exceptional wall structure. Its lightweight design contributes to reduced production costs, thereby enhancing market competitiveness. This pipe, with its easy connectivity, accessory installation, and reliable quality, has found widespread use in various applications, often replacing traditional concrete and iron pipes.Plastic PVC Wood WPC Door Panel Making Machine

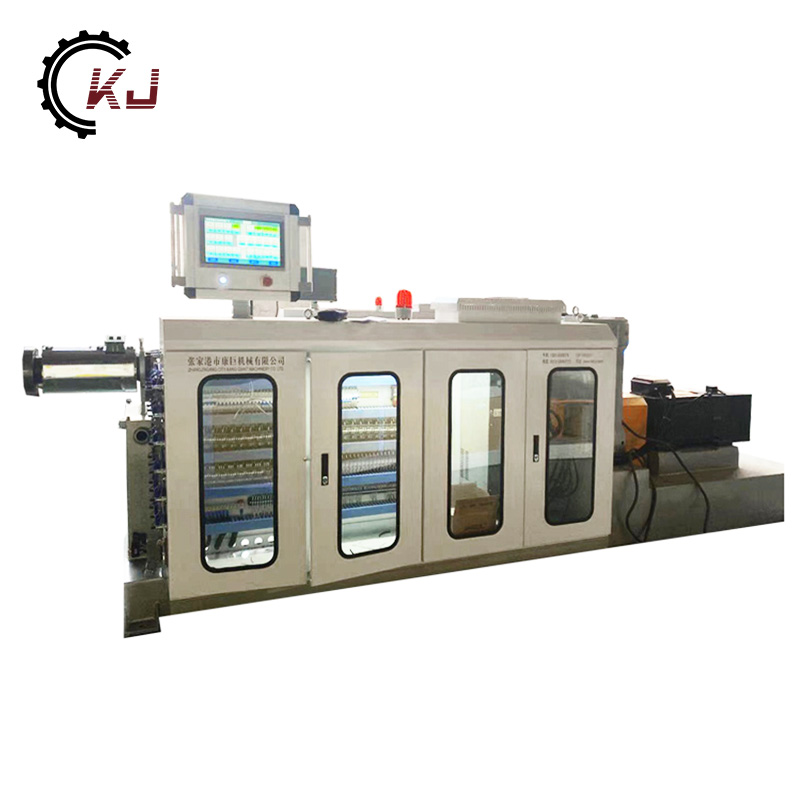

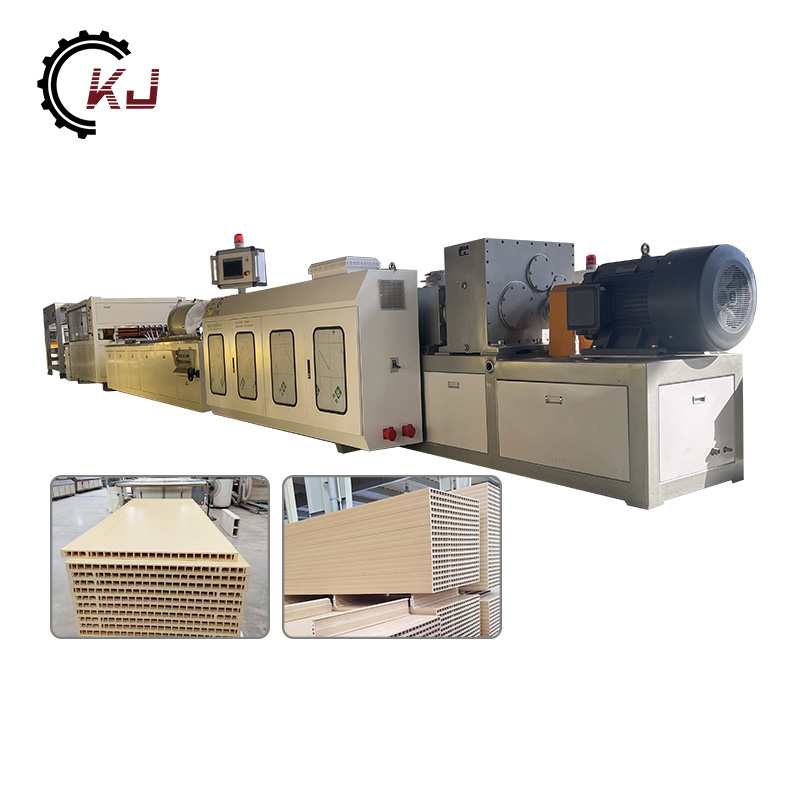

Plastic pvc wood wpc door panel making machine is mainly used for the width WPC door and windows board extrusion. WPC door and windows board production line includes the following major parts: conical twin screw extruder, vacuum forming table, spary cooling tank, board haul off machine, board cutting machine, board stacker.Plastic Crusher Machine

High quality waste shredder/plastic crusher machine is used to crush plastic, rubber, fiber, paper, wood, large hollow materials (large containers such as plastic drums) and various mixed wastes, especially those containing metal, or pre-crushed tools such as sand. scrap. The crushing hollow material can be equipped with a press device to increase the output. A rotating screen can also be added to control the discharge size. When the double shaft shredder is running at low speed, noise and dust can reach high environmental standards.WPC Ceiling Panel Production Line

The WPC Ceiling Panel Production Line from Kangju Supplier specializes in manufacturing PVC wall panels, typically ranging in width from 250mm to 300mm, with varying section shapes and heights. The surface finish of these PVC ceiling panels can be enhanced through a dual hot stamping printing process or lamination, allowing for the creation of intricate marble or wooden designs on the product's exterior.