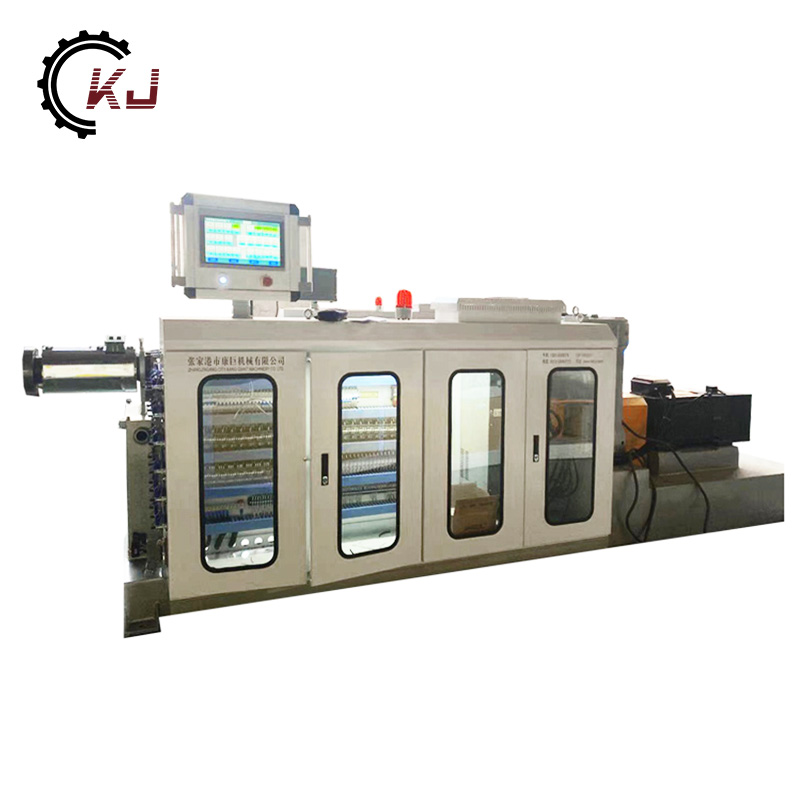

China polyethylene plastic making machine Manufacturer, Supplier, Factory

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for polyethylene plastic making machine,PE pipe making machine,polyethylene PE pipe making machine,polyethylene plastic PE pipe extrusion machine, "Quality first, Price lowest, Service best" is the spirit of our company. We sincerely welcome you to visit our company and negotiate mutual business!

polyethylene plastic making machine, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

Hot Products

PE Pulverizer Machine

The PE Pulverizer Machine machine of the SMF series are available with diameter from 300 to 800 mm. These plastic pulverizer machines are high speed, precision grinders for the processing of medium hard, impact resistant and friable materials. The material to be pulverized is introduced through the centre of a vertically fixed grinding disc which is mounted concentrically with an identical high speed rotating disc. Centrifugal force carries the material through the grinding area and the resulting powder is collected with a blower and cyclone system. Depending on the application the machines can be equipped with one piece grinding discs or grinding segments.Wood Plastic Composite WPC Machine

The Wood Plastic Composite WPC Machine is a crucial component of the WPC machine. It combines and melts the wood and plastic materials, forming a uniform mixture. This mixture is then forced through a die to shape it into the desired profile or board. The die is a critical component that shapes the WPC material into the desired profile or board. After exiting the die, the product moves onto a calibration table, which helps in maintaining its shape and dimensions.Polyethylene Plastic Recycling Processing Line

The Polyethylene Plastic Recycling Processing Line is a comprehensive system designed to effectively recover and transform waste polyethylene plastic into reusable materials. This recycling line incorporates advanced technology and efficient processes to ensure maximum resource utilization and environmental sustainability.Kangju is a professional China Polyethylene Plastic Recycling Processing Line manufacturer and supplier.polyethylene plastic PE pipe making machine

As the professional manufacturer, we would like to provide you high quality polyethylene plastic PE pipe making machine.Plastic Film Recycling Machine Production Line

The Kangju high quality plastic film recycling machine production line can be designed according to the dirtiness of the PP PE film/bag and ensure the quality of the final product.Coordinate the production line with subsequent programming work (granulation system), which will turn waste and dirty PP PE films/bags into PP PE granular materials and produce new PP PE products.ASA PVC Roofing Tile Machine

The Kangju ASA PVC Roofing Tile Machine is primarily utilized for manufacturing plastic glazed tiles, which are extensively applied in various settings such as garden-style factories, tourist attractions, pavilions, hotels, and residential buildings.