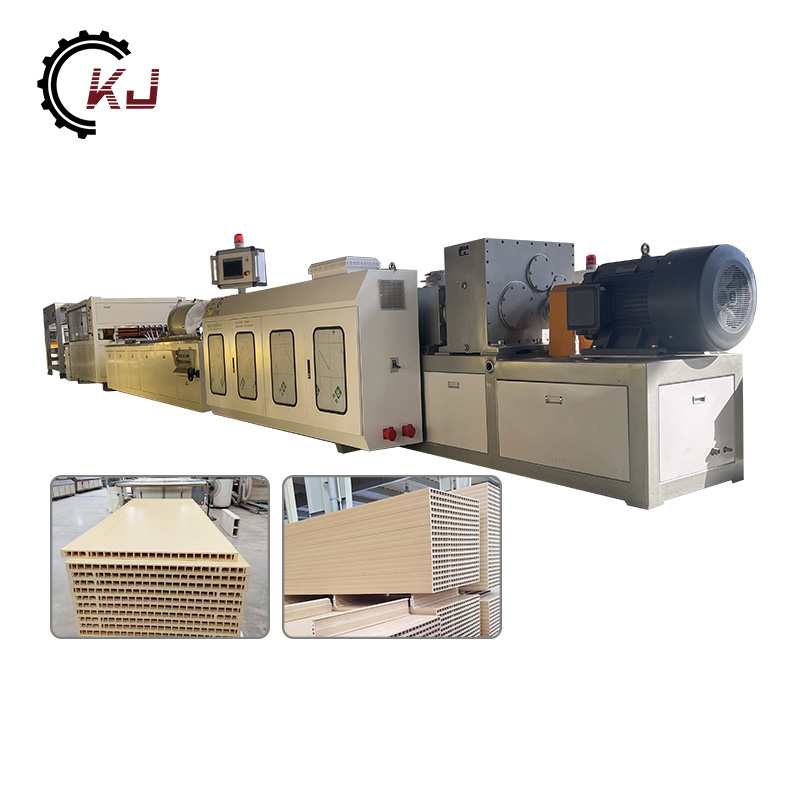

China WPC Louver Panel Making Machine Extruder Production Line Manufacturer, Supplier, Factory

We now have a skilled, performance team to supply good quality services for our consumer. We often follow the tenet of customer-oriented, details-focused for WPC Louver Panel Making Machine Extruder Production Line,Durable Plastic PVC Cable Channel Trunking Profile Making Machine,Pvc Special Shaped Profile Extruder Machine,Plastic Profile Extrusion Equipment,PVC WPC Fence Door Ceiling Wall Panel Board Sheet Extrusion Making Machine Line, Our solutions are widely recognized and reliable by users and can satisfy continuously acquiring economic and social needs.

WPC Louver Panel Making Machine Extruder Production Line, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

Hot Products

PE Sleeve Pipe Calibrator

The function of the sizing sleeve is mainly to cool down the tube blank of the PE Sleeve Pipe Calibrator, and fix the outer diameter of the tube blank and trim the surface of the tube.Wood plastic composite products manufacturing machine

Wood plastic composite products manufacturing machine Wood-plastic floor paneling can avoid the disadvantages of traditional wooden decorative materials, and there will be no problems such as cracking and deformation during use. What’s more, WPC is also flame retardant, making it ideal for indoor and outdoor installations. Wood-plastic flooring can not only make up for the shortcomings of traditional materials, but also extend the service life and reduce the application cost of panels.Automatic PET Sheet Production Line

The screw is tailored with a parallel twin-screw configuration, specifically for PET applications. It features venting capabilities, uniform plasticization, an oblique three-roll calender design, and an L-shaped calender design. To ensure the product's superior toughness, the roller temperature can be precisely adjusted via a mold temperature controller. The Automatic PET Sheet Production Line from Zhejiang Kangju Machinery boasts high transparency and comes equipped with a pre-coated silicone oil device, guaranteeing smooth sheet release during secondary processing. Additionally, thickness measurements are accurately taken with a dial gauge, and the winding process is automatically tensioned for consistent results.PVC Edge Banding Production Line

Introducing the PVC Edge Banding Production Line – a versatile and highly efficient solution for your edge banding needs. This fully automated production line is designed for high volume, low-waste production of PVC edge banding tape, made to the highest standards of quality and precision.PE Pipe Sleeve with Double Water Ring

Sizing sleeves play a key role in the production process of PE Pipe Sleeve with Double Water Ring. It is not only responsible for effectively cooling the tube blank to prevent it from being deformed or damaged during subsequent processing, but also ensuring that the outer diameter of the tube blank reaches the predetermined standard size and ensuring the consistency of product quality.HDPE Pipe Extrusion Machine

The high speed HDPE Pipe Extrusion Machine adapts the optimized longer L/C ratio screw,applied on PPR,PE and formulation materialextrusion,has advantages on low wearing,low energy consumption, high efficiency,uniform and stable extrusion.