China Durable Plastic PVC Cable Channel Trunking Profile Making Machine Manufacturer, Supplier, Factory

Our pursuit and company goal is to "Always satisfy our customer requirements". We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for Durable Plastic PVC Cable Channel Trunking Profile Making Machine,Pvc Special Shaped Profile Extruder Machine,Plastic Profile Extrusion Equipment,WPC Louver Panel Making Machine Extruder Production Line,PVC WPC Fence Door Ceiling Wall Panel Board Sheet Extrusion Making Machine Line, For more information and facts, you should never wait to make contact with us. All inquiries from you may be highly appreciated.

Durable Plastic PVC Cable Channel Trunking Profile Making Machine, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant expert knowledge, to develop advanced production equipment and production process , to create the first-call quality merchandise, reasonable price , high quality of service , quick delivery , to present you create new value .

Hot Products

PVC Edge Band Production Line

PVC edge band production line extrusion machine with double screw extruder is used to produce PVC edge banding tape. For different size edge banding will need change mould. This type machine can be 2 cavity, 4 cavity, 6 cavity or 8 cavity. The size of edge banding, width 19mm-54mm and thickness 0.4mm-2mm.PE Pulverizer Machine

The PE Pulverizer Machine machine of the SMF series are available with diameter from 300 to 800 mm. These plastic pulverizer machines are high speed, precision grinders for the processing of medium hard, impact resistant and friable materials. The material to be pulverized is introduced through the centre of a vertically fixed grinding disc which is mounted concentrically with an identical high speed rotating disc. Centrifugal force carries the material through the grinding area and the resulting powder is collected with a blower and cyclone system. Depending on the application the machines can be equipped with one piece grinding discs or grinding segments.PVC Grinding Machine

The newly introduced Kangju Manufacturer PVC Grinding Machine falls under the category of Disc-type pulverizers, featuring discs with diameters ranging from 350mm to 800mm. This high-speed, precision PVC Grinding Machine is specifically designed for processing medium-hard, impact-resistant, and fragile materials, encompassing various plastics like PE, PVC, PP, ABS, PA, EVA, PET, PS, PPS, EPS, PC, Foam, as well as Cow leather. It offers efficient and precise grinding capabilities for these materials.Plastic Granulator

Let us introduce you to Kangju's superior Plastic Granulator, offering you a comprehensive understanding of its capabilities. We eagerly anticipate our continued partnership with our valued customers, both new and loyal, as we work towards a shared, brighter future.Wood-Plastic Composite Panel Production Line

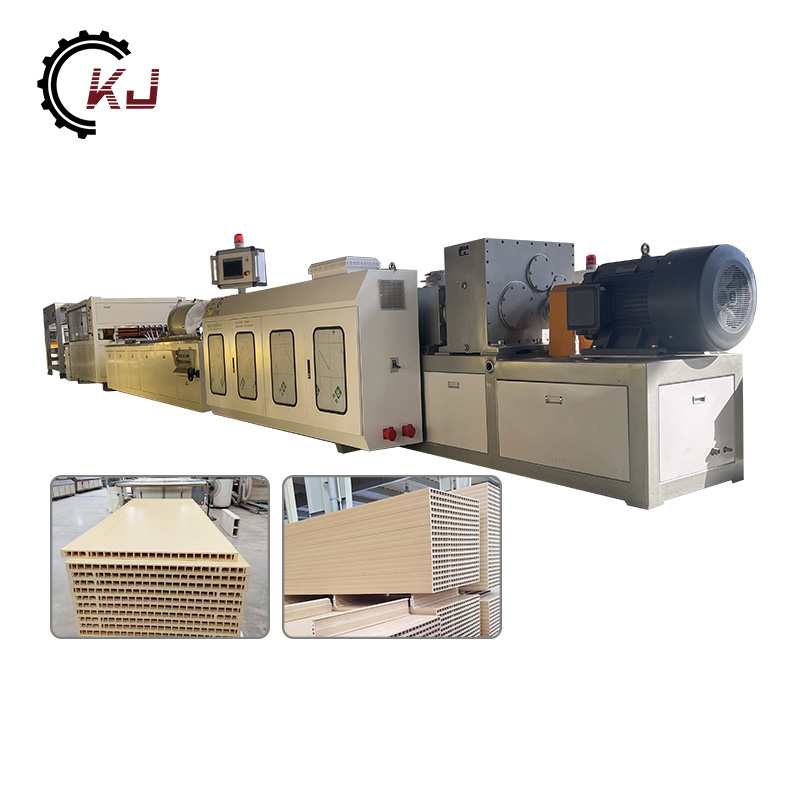

Kangju Factory offers a Wood-Plastic Composite Panel Production Line specifically designed for crafting outdoor applications such as wood-plastic paving, fences, columns, pallets, floors, chairs, and wall panels. This comprehensive extrusion line comprises a conical twin-screw extruder, calibration platform, pulling and cutting machine equipped with a vacuum device, and a product stacker. Through a series of processes including mixing, granulation, extrusion, embossing, sanding, and brushing, the resulting PE WPC profiles mimic the appearance and texture of natural wood, offering an exceptional alternative.WPC Ceiling Panel Production Line

The WPC Ceiling Panel Production Line from Kangju Supplier specializes in manufacturing PVC wall panels, typically ranging in width from 250mm to 300mm, with varying section shapes and heights. The surface finish of these PVC ceiling panels can be enhanced through a dual hot stamping printing process or lamination, allowing for the creation of intricate marble or wooden designs on the product's exterior.